Powering Ahead: Global Trends Shaping the Future of EV Manufacturing by 2030

- 1881 Software

- Jun 30, 2025

- 3 min read

As the global push toward sustainability accelerates, electric vehicle (EV) manufacturing is undergoing a rapid transformation. With governments setting aggressive emissions targets, automakers ramping up their electric portfolios, and consumers becoming increasingly eco-conscious, the next decade will be pivotal for the EV industry. By 2030, we can expect to see significant shifts in how EVs are designed, produced, and integrated into daily life. Here’s a look at the key global trends that will define the future of EV manufacturing.

1. Surge in Global EV Adoption

The most evident trend is the rising global demand for EVs. Countries across Europe, Asia, and North America are setting timelines to phase out internal combustion engine (ICE) vehicles. For example, the European Union plans to ban the sale of new petrol and diesel cars by 2035, while several automakers, including GM and Volvo, have committed to going all-electric within the next decade.

This growing demand is forcing traditional manufacturers to restructure operations, build EV-specific production lines, and invest heavily in R&D. As economies of scale improve, production costs are expected to decline, further fueling adoption.

2. Localized and Diversified Manufacturing Hubs

Global supply chain disruptions during the COVID-19 pandemic and geopolitical tensions have highlighted the risks of over-reliance on a few regions. In response, automakers are localizing their production to mitigate risks and meet regional demand more efficiently.

Asia, particularly China, remains a dominant force in EV manufacturing, but other regions are catching up. The U.S. is investing in domestic battery production, while Eastern Europe and Southeast Asia are becoming attractive locations for EV assembly plants due to lower costs and strategic trade access.

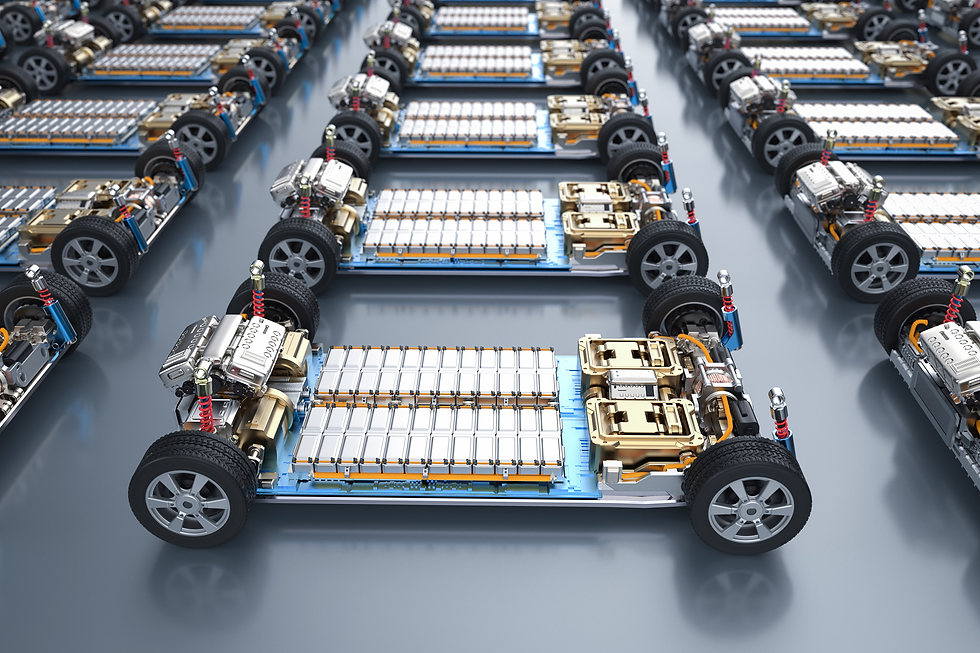

3. Battery Innovation and Next-Gen Materials

Battery technology is the cornerstone of EV performance, cost, and sustainability. By 2030, major breakthroughs are expected in solid-state batteries, which offer higher energy density, faster charging times, and improved safety over current lithium-ion technology.

Additionally, manufacturers are exploring alternatives to expensive and rare materials like cobalt and nickel. Efforts to create more sustainable and recyclable battery chemistries will not only lower costs but also address environmental concerns associated with mining and disposal.

4. Automation and Smart Manufacturing

The EV manufacturing process is becoming increasingly automated, leveraging robotics, AI, and data analytics to optimize efficiency and quality. Smart factories—equipped with real-time monitoring systems and predictive maintenance—will become the norm by 2030.

These intelligent manufacturing ecosystems enable rapid customization, lower defect rates, and quicker adaptation to new model designs. This is particularly important for EVs, where technological updates occur much faster than with traditional vehicles.

5. Sustainability Across the Value Chain

Sustainability is no longer limited to the vehicle itself but encompasses the entire manufacturing lifecycle. Automakers are focusing on reducing the carbon footprint of their factories, using renewable energy sources, and creating closed-loop systems where materials are reused or recycled.

Expect to see more green factories powered by solar and wind energy, water-efficient processes, and zero-waste initiatives. As ESG (Environmental, Social, and Governance) standards gain prominence, sustainable manufacturing will be a competitive differentiator.

6. Rise of Vertical Integration

To gain more control over quality, costs, and supply, companies are increasingly adopting vertical integration strategies. Tesla, for instance, produces its own batteries, software, and even some raw materials, setting a precedent for others to follow.

By 2030, more automakers and suppliers will build in-house capabilities across the value chain—from battery chemistry to vehicle software platforms—ensuring greater agility and resilience.

Conclusion

The road to 2030 will redefine EV manufacturing as a high-tech, globally integrated, and sustainable industry. Success will hinge on innovation, adaptability, and a long-term commitment to environmental stewardship. Automakers that embrace these trends will not only lead the EV revolution but also set new standards for the future of mobility.

Comments